The Sheet Metal Stamping Parts manufactured in China since 2001 is ISO9001 Certified and is one of the Top manufacturer’s in the respective region. Using the most sophisticated manufacturing technologies available.

Specialized in the conception and manufacturing of OEM and ODM in high mix of Small, Medium and High volume to customers who need a dependable High Quality / Low Cost Flexibility manufacturing partner. From front to end design and manufacturing. we offer a Total Solution without compromising on Today’s Quality and Reliability in the Industry Standards.

Manufacturing

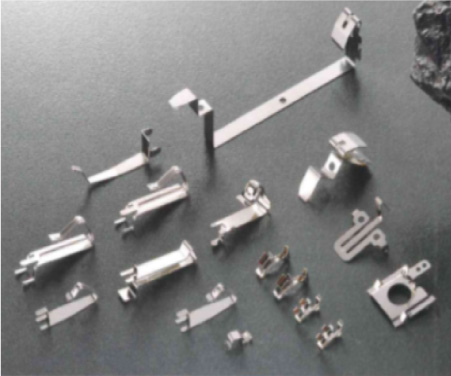

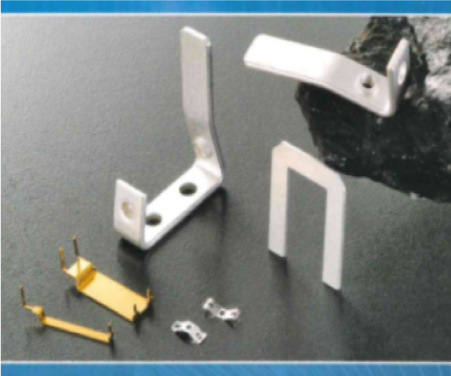

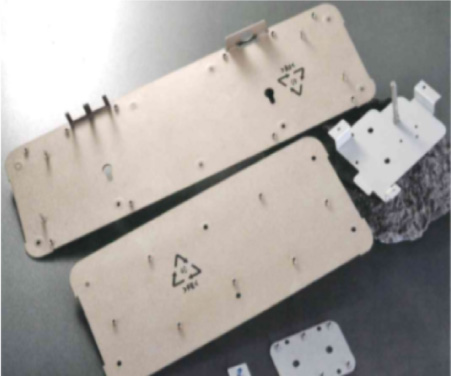

We provides Sheet Metal, Heat Sink, Spring Contact, Battery Contact & Metal Stamping solution for electronics, audio, automotive, gaming, medical, military and home appliances industries etc.

Our manufacturing strength in providing customer needs throughout their entire project including :-

- Tooling Design and Construction

- DFM, tool technology evaluation

- Low to high volume manufacturing

- Project management throughout tooling design, prototyping and into manufacturing

- Tooling Maintenance

Tooling Making & Maintenance

Precise Tooling contribute to produce a high quality product. Our years of experience and integrated application of the high speed and precise equipment contributes a sound precision and endurance to our Tooling making.

The Maintenance section supports our production in enhancing productivity and achieving high levels of efficiency, precision and quality through periodic preventive maintenance and repair of Tooling.

Manufacturing Facilities

We boast a variety of presses and other equipment for metal processing as well as a group of versatile and qualified technicians. The production is strictly controlled on each step in accordance with operation instructions. Our Engineering Department devotes to rational improvement on processes so as to enhance the production process for the Zero defect quality target.

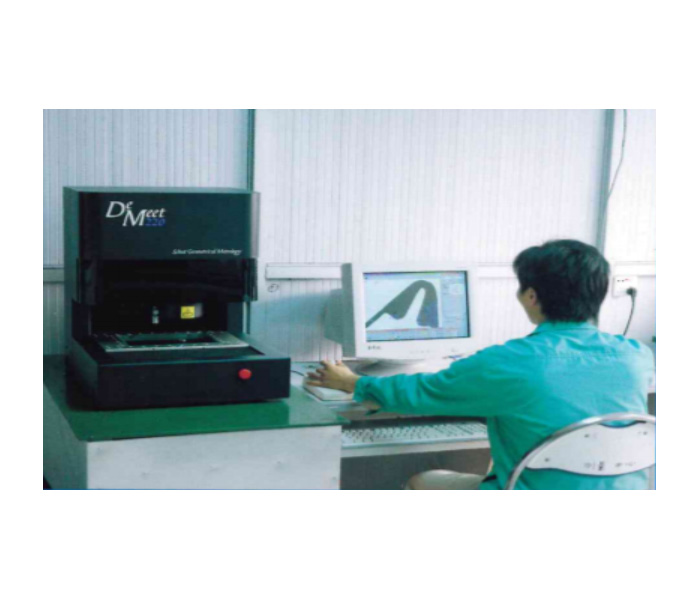

Quality Assurance

The Quality Assurance Department inspect and buys off parts for mass production and for customers using stringent AQL sampling, measuring and inspection equipment to ensure all parts conform to or exceed our customers’ requirements.

Quality Certification